Our extensive manufacturing capabilities enable us to produce precision metallic powertrain systems, advanced aerial work platforms and durable industrial & agricultural assemblies.

Linamar global operations are divided into regional groups with vertically integrated operations combining expertise in light metal casting, forging, machining and assembly, metal forming for both the global electrified and traditionally powered vehicle markets.

Linamar has a diverse range of capabilities that are continually evolving to better meet the needs of a global market.

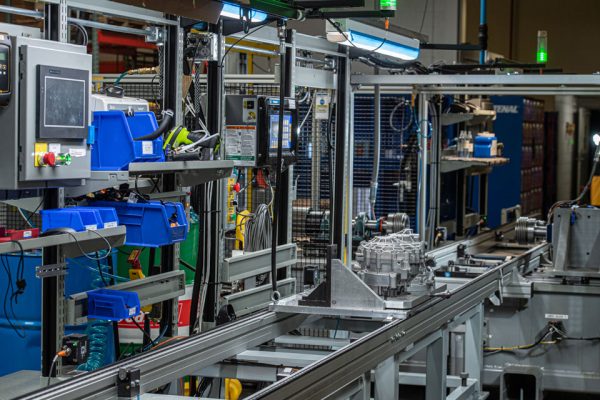

Machining & Assembly

- Advanced Automation & Robotics

- CNC Expertise

- Complex Assemblies

- Hydroforming

- Heat Treatment

Metal Forming

- Robotic Welding

- Laser cutting

- Metal Forming

- Stamping

- Painting

- Assembly

Forging

- Hatebur High Speed Hot Horizontal Forging

- Conventional Vertical Forging

- Cold Forming

- Ring Rolling

- Radial Forging

Light Metal Casting

- Gravity & Low Pressure Aluminum Die Casting

- High Pressure Aluminum & Magnesium Die Casting

Markets

Diversification is one of our strategies for success.

We envision a future where we continue to be competitive and diversify into six strategic markets. It is a 100-year plan geared to a changing world with a vision for continued, long-term sustainable growth. This is a vision meant to drive a positive impact for all the Linamar stakeholders.

McLaren Engineering is Linamar’s leading-edge technology and product development team for our mobility segment.

The foundation for Linamar’s technical advancements is rooted in the expertise of McLaren Engineering. Purchased by Linamar in 2003, McLaren provides design, development, integration, manufacturing, and testing capabilities that provide our customers a world-class, full-service supplier partner that develops complete vehicle powertrain & driveline systems for both the global electrified and traditionally powered vehicles.

The Linamar Product Development System is a disciplined approach to the product development cycle as outlined by the Linamar GOS (Global Operating System) Playbook.

The step-by-step process begins with design creation through the use of advanced industry CAD and CAE software packages, followed by Design Validation (DV) and Production Validation (PV) level testing of physical parts in our own development facilities and lastly, the release of the approved production design into the Linamar manufacturing environment.

Linamar and McLaren collaborate during this process to ensure seamless integration from initial concept through to program end-of-life.

Rapid Prototyping

Specialty Fabrication and Low Volume Builds

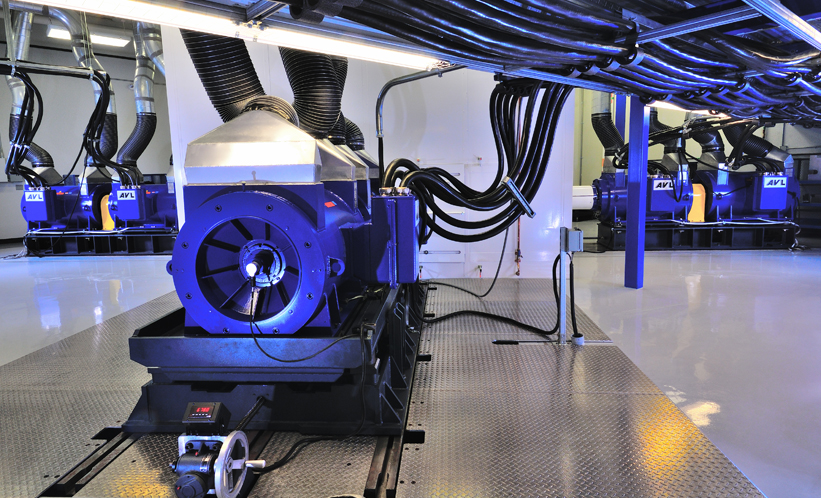

Driveline TE Cell

Driveline NVH Cell

Rotary Actuator Cell

Engine Testing Services Matrix

Transient Engine Development Cell

Ancillary Capabilities

Thermal Studies

Impact Testing

eLIN

eLIN focuses on developing electrified product solutions for all business lines, developing electrification strategies in four key areas: Power Generation, Power Storage, Propulsion Systems, and Structural & Chassis offerings for electrified vehicles.

eLIN unified product solutions are driving advancements in electrification, leveraging Linamar’s capabilities, providing innovative solutions to our customers.

Linamar Global Locations

PRESS RELEASES

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- Show all years

Linamar Delivers Record Sales over $10 Billion, Exceptional Free Cash Flow and Another Year of Double-Digit Earnings Growth

5 3 月, 2025Linamar Announces Investments in Automotive Technologies Supported by the Canadian Federal and Ontario Provincial Governments

28 1 月, 2025Careers

Together, we are Powering Futures.