Linamar’s portfolio for the past several years has been continually transitioning to increased offerings of products that positively contribute to reduced vehicle fuel consumption and CO2 emissions. This is in alignment with government legislation in many of our key markets and in conjunction with our OEM customers’ strategies and goals related to CAFÉ (Corporate Average Fuel Economy) and emissions reduction.

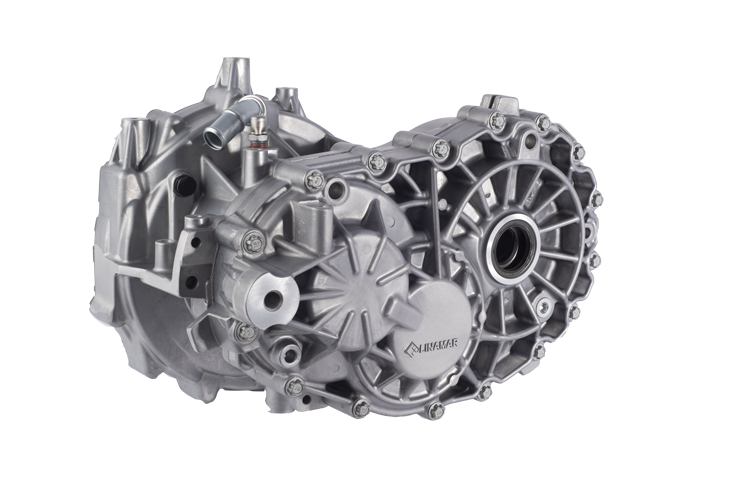

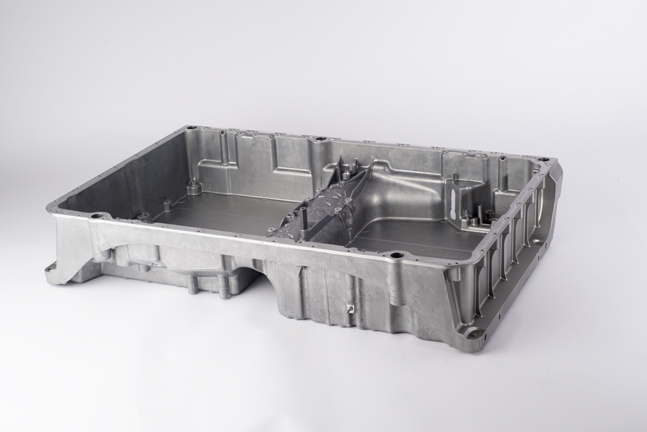

In fact, sales of components for next generation, fuel efficient 7, 8, 9 and 10 speed transmission programs grew from less than 5% of Linamar’s total light vehicle revenues in 2014 to more than 30% in 2019. These components and modules will replace less fuel efficient 4, 5 and 6 speed transmissions that are operating currently in the on-road vehicle population. Additionally, on the internal combustion engine (ICE) side, sales of components for lower displacement fuel efficient 3 and 4 cylinder engines has grown from 14% of Linamar’s total light vehicle revenues in 2014 to more than 40% in 2019. These components and modules will replace less fuel efficient higher displacement V8, V6 engines that are operating currently in the on-road vehicle population. Along with our higher level of sales penetration in lighter weight aluminum and magnesium metal components, an area of the business that is significantly growing as well, Linamar is significantly contributing to the overall trends seen in the industry and will continue in the years going forward.

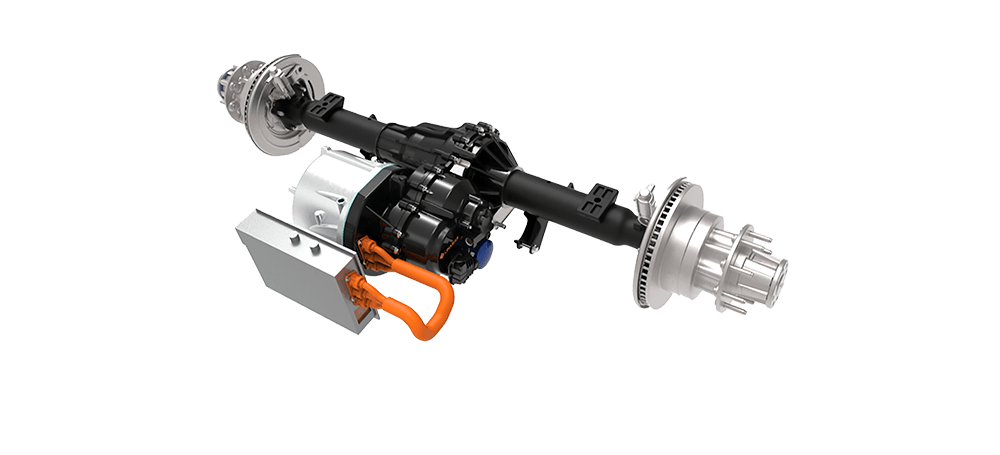

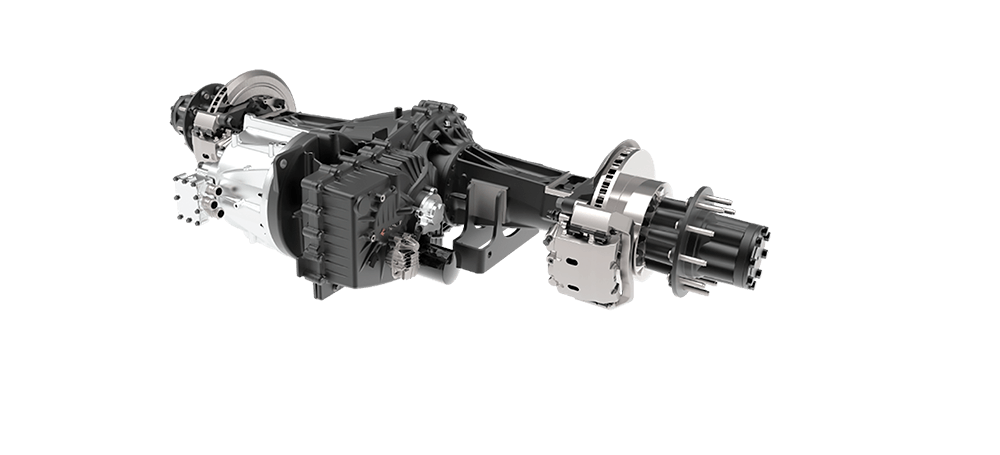

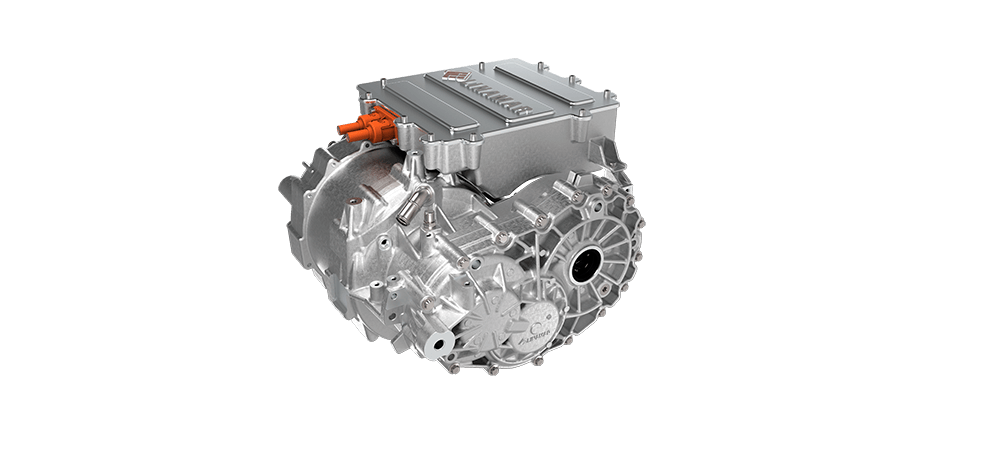

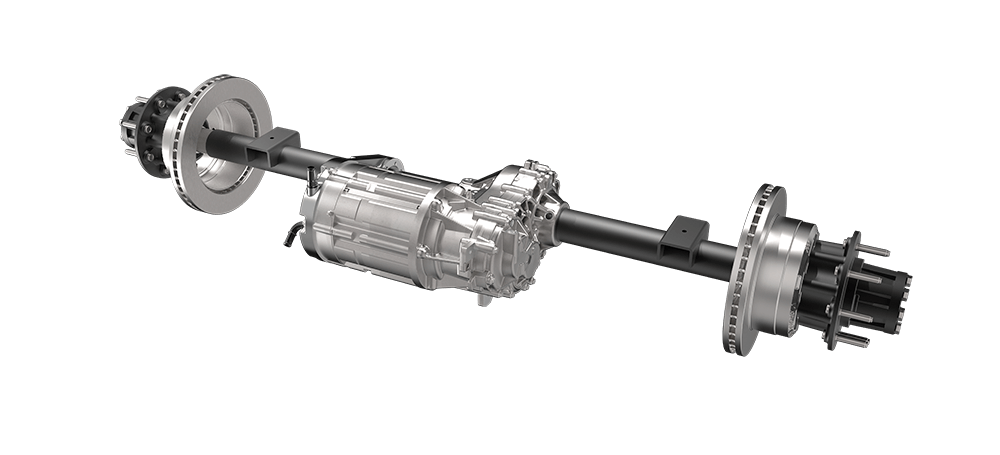

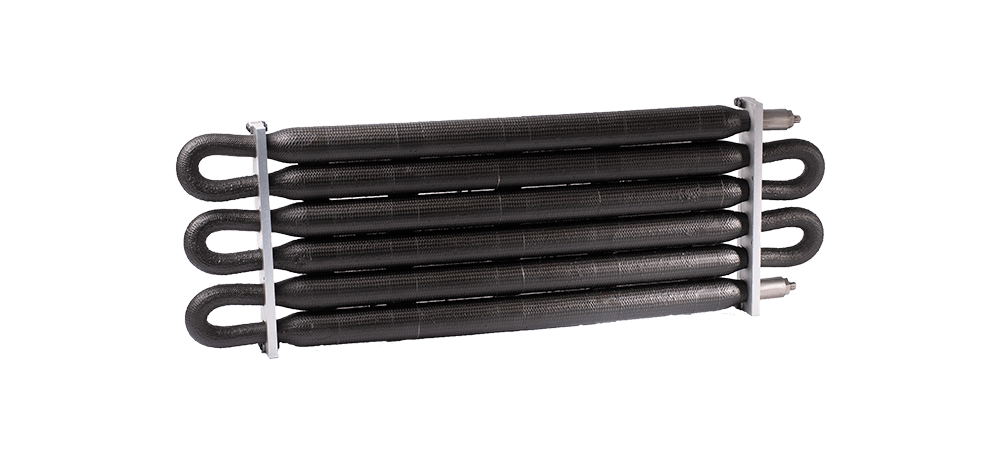

Although the ICE technology improvements and lightweighting are a significant contributor in this effort to lessen the auto industry’s impact on climate change, Linamar acknowledges the long-term transition happening beyond that which is the shift from ICE to Electrified Vehicles. Linamar is investing heavily in R&D, design/validation expertise and production equipment necessary to provide products needed in an electrified auto industry future. Linamar has products in hybrid vehicles, full electric BEV (battery electric vehicles) and is investing beyond that in hydrogen fuel cell technologies for the long-term. Linamar has a increased its portfolio of products specific for electric applications including full eAxle systems, electric drive unit (EDU) housings, motor housings, battery trays among others. In addition, Linamar has invested in research and design of complex Commercial Truck eAxle systems.

The increase in structural light metal castings over the past several years is another example of increased addressable content to non-ICE powertrain components.

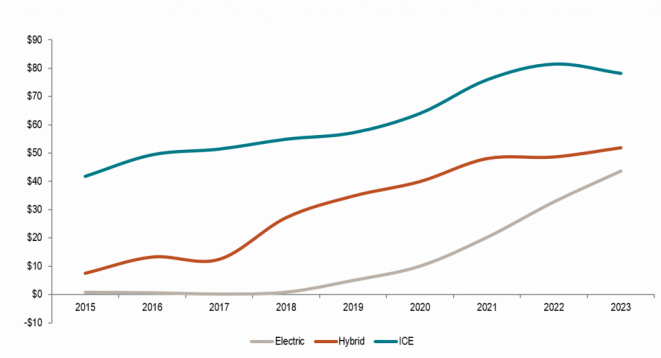

The global market share of pure Battery Electric Vehicles (BEV) of the overall light vehicle production is still relatively low today, at only 2-3% of the market. But Linamar’s focus in this area has seen a high number of New Business Wins for electrified programs. In fact, over the course of the next 4 years, Linamar’s global Content Per Vehicle (CPV) on pure BEVs will increase from less than $5 in 2019 to nearly $42 by 2023, based solely on contracts already in hand, proof that we have a commitment to doing our part to support this transition to a lower carbon automotive future.