Capabilities

Our extensive manufacturing capabilities enable us to produce precision metallic powertrain systems, advanced aerial work platforms and durable industrial & agricultural assemblies.

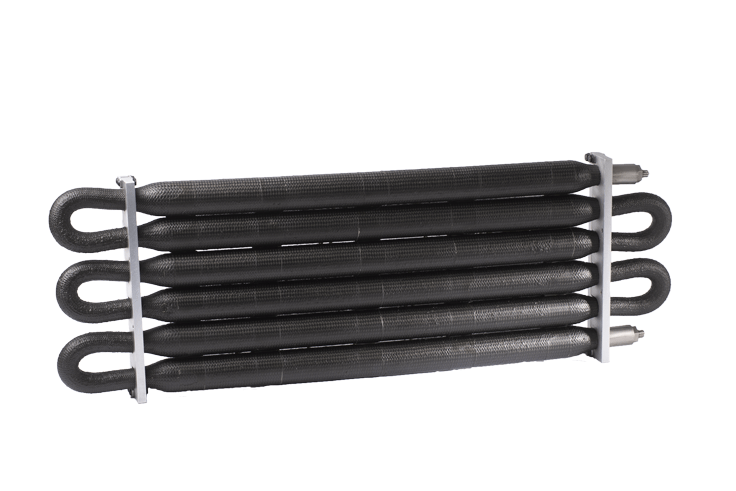

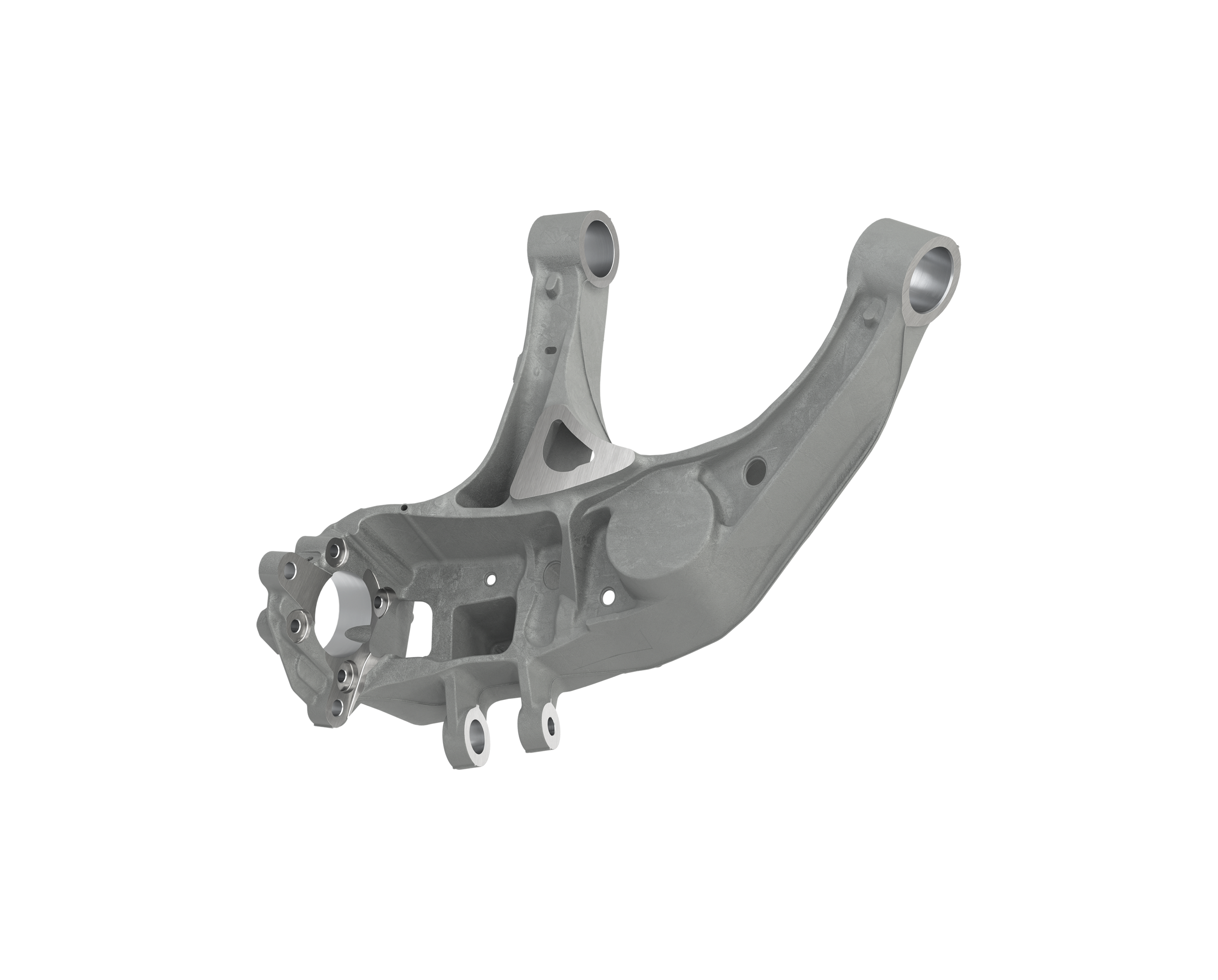

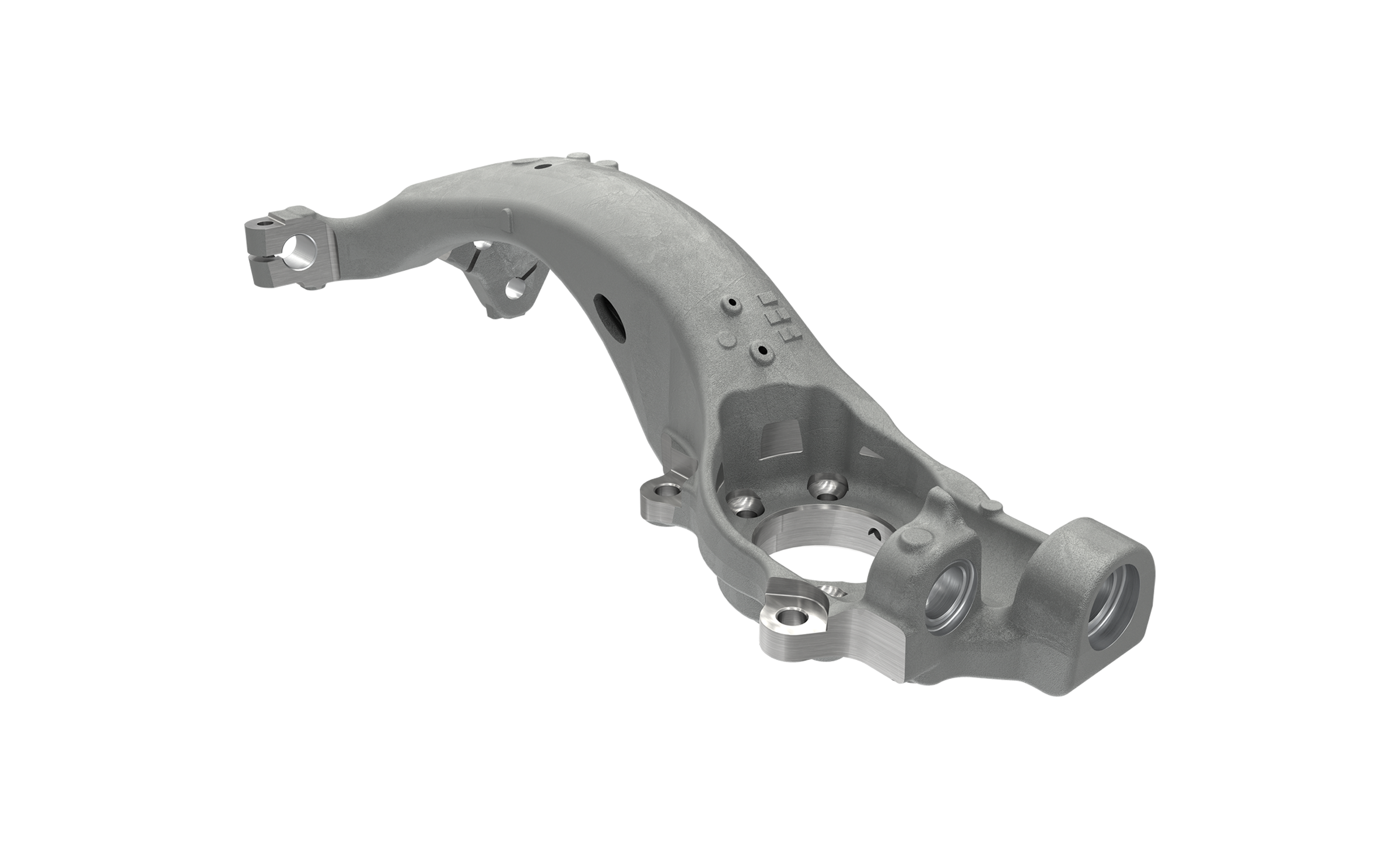

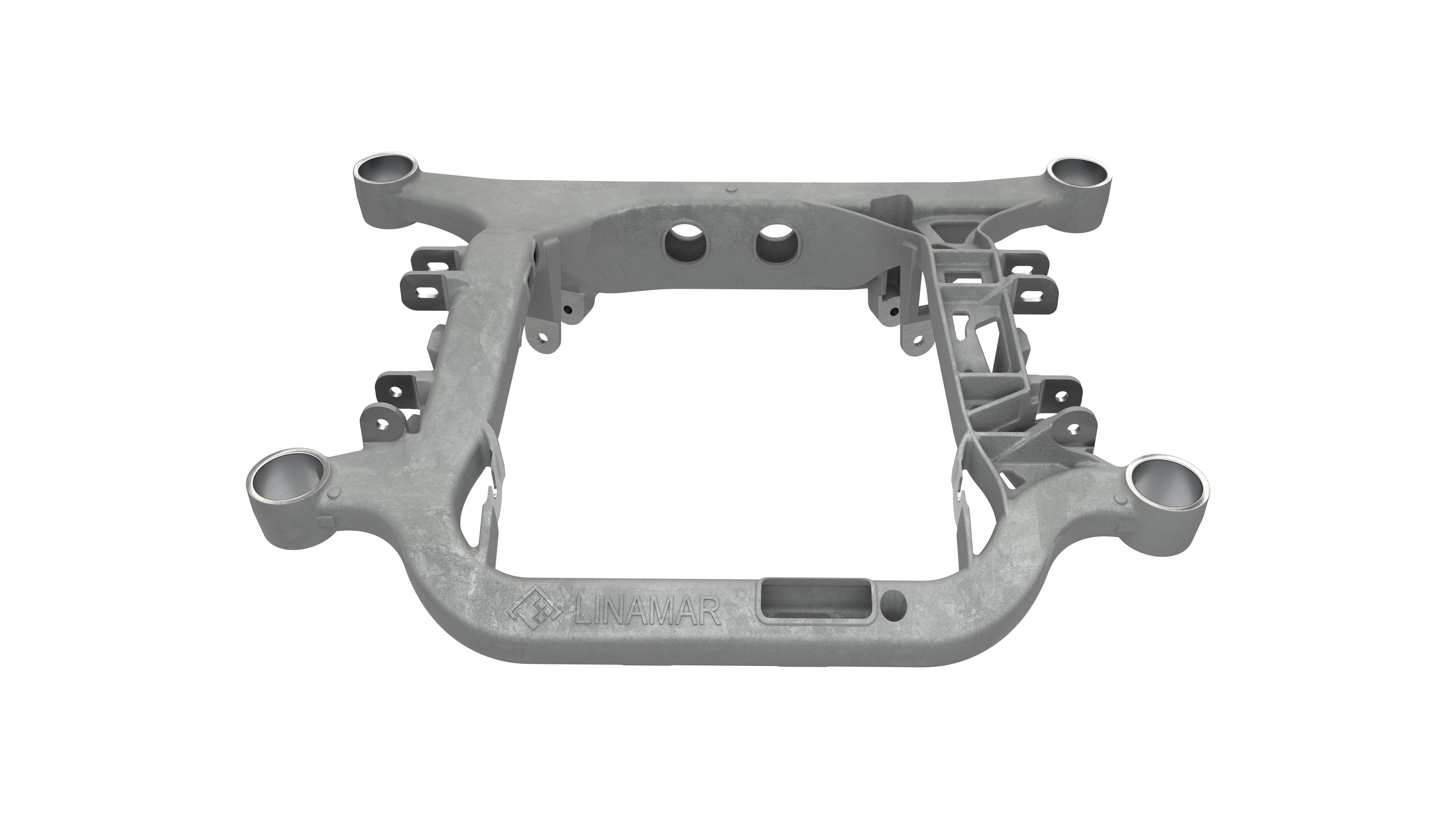

Linamar global operations are divided into regional groups with vertically integrated operations combining expertise in light metal casting, forging, machining and assembly, metal forming for both the global electrified and traditionally powered vehicle markets.

Linamar has a diverse range of capabilities that are continually evolving to better meet the needs of a global market.

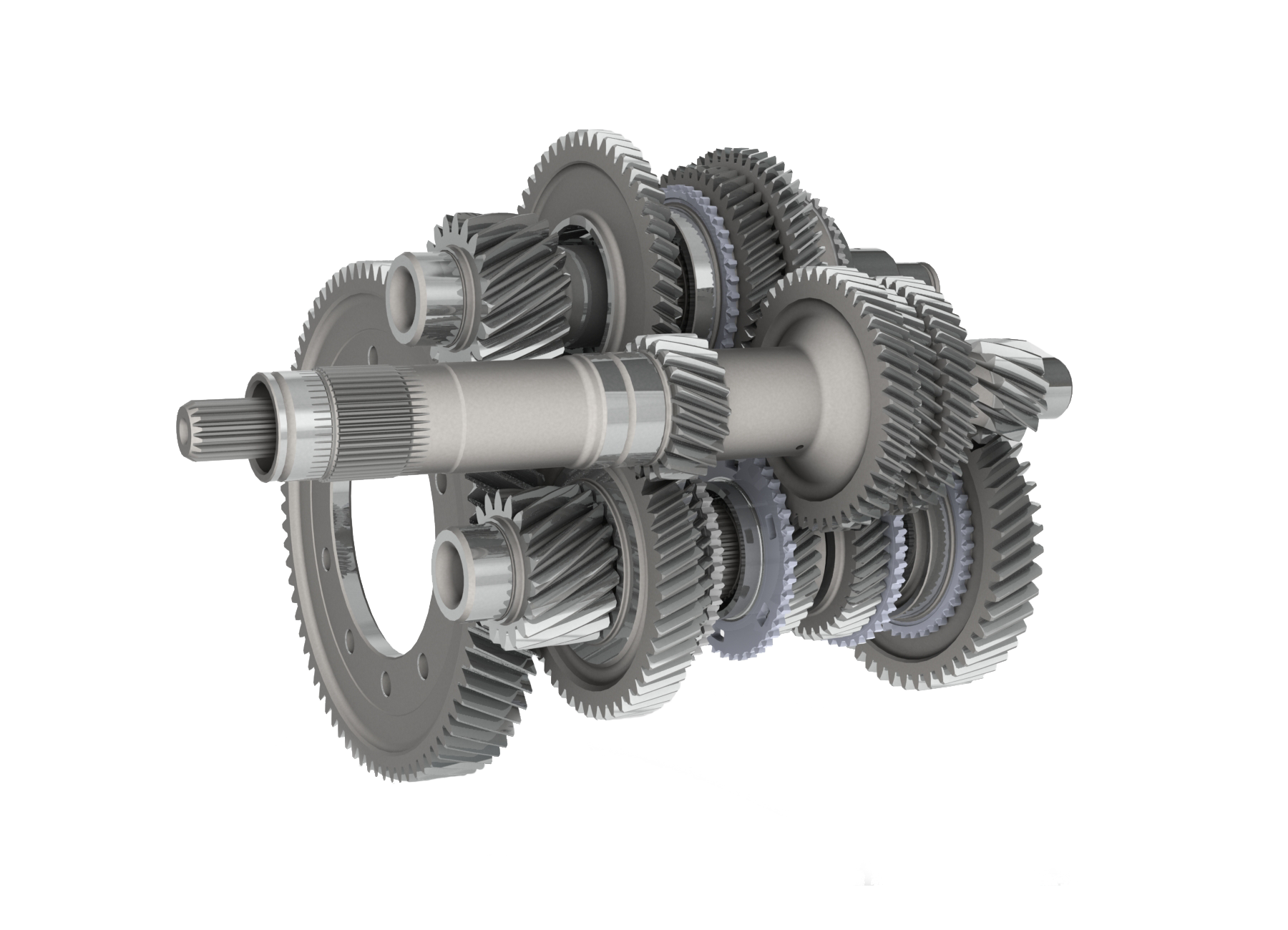

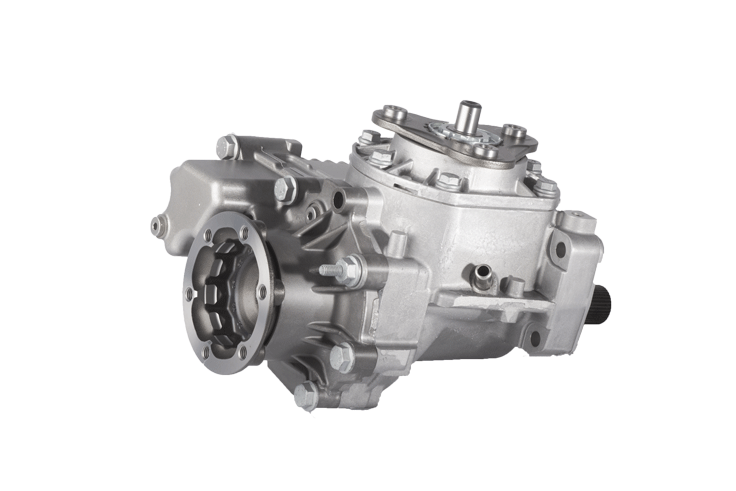

Machining & Assembly

- Advanced Automation & Robotics

- CNC Expertise

- Complex Assemblies

- Hydroforming

- Heat Treatment

Metal Forming

- Robotic Welding

- Laser cutting

- Metal Forming

- Stamping

- Painting

- Assembly

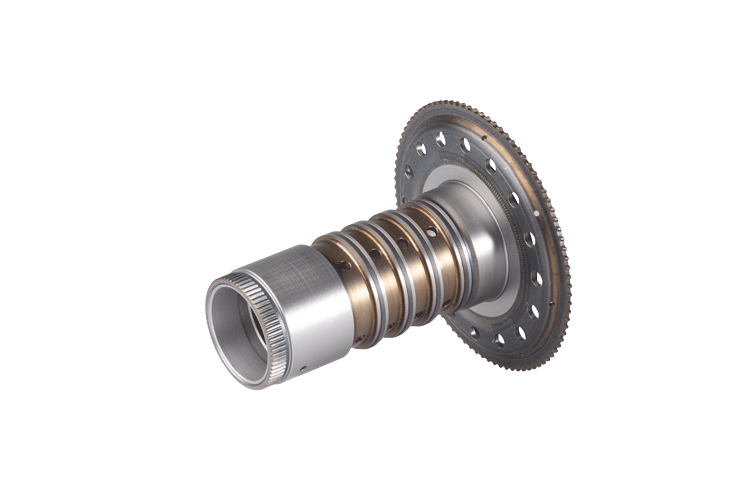

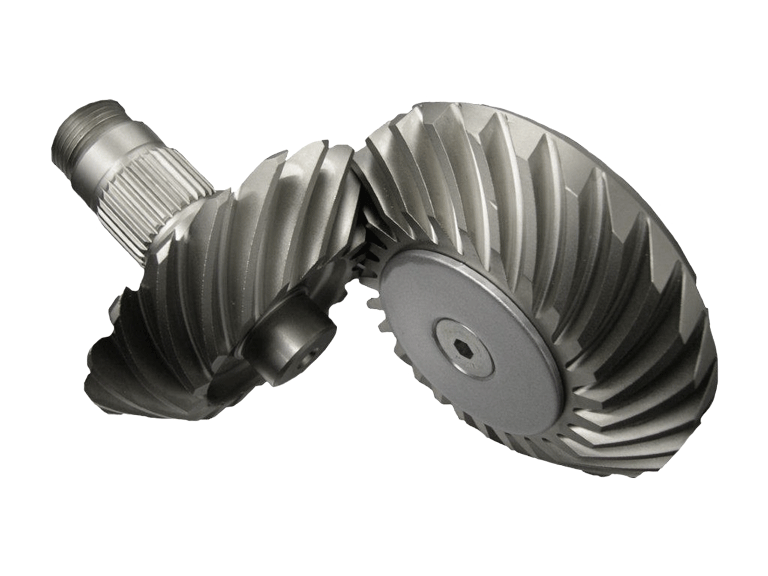

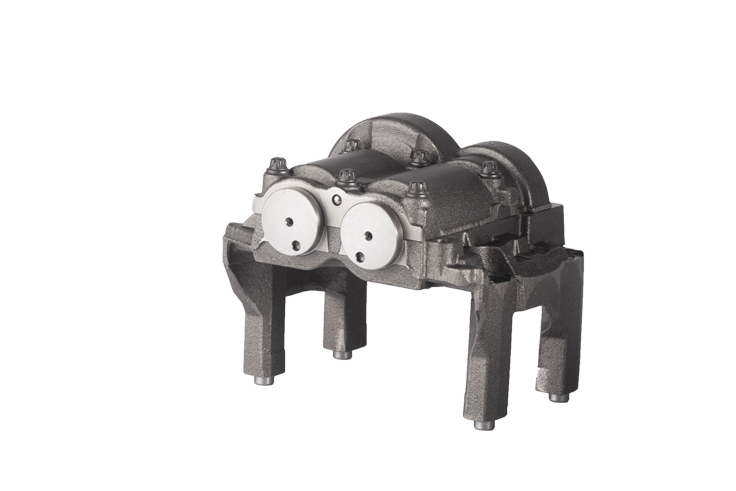

Forging

- Hatebur High Speed Hot Horizontal Forging

- Conventional Vertical Forging

- Cold Forming

- Ring Rolling

- Radial Forging

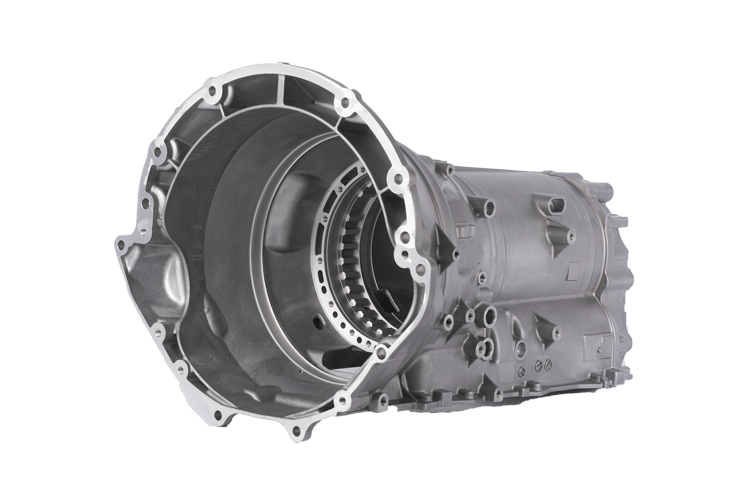

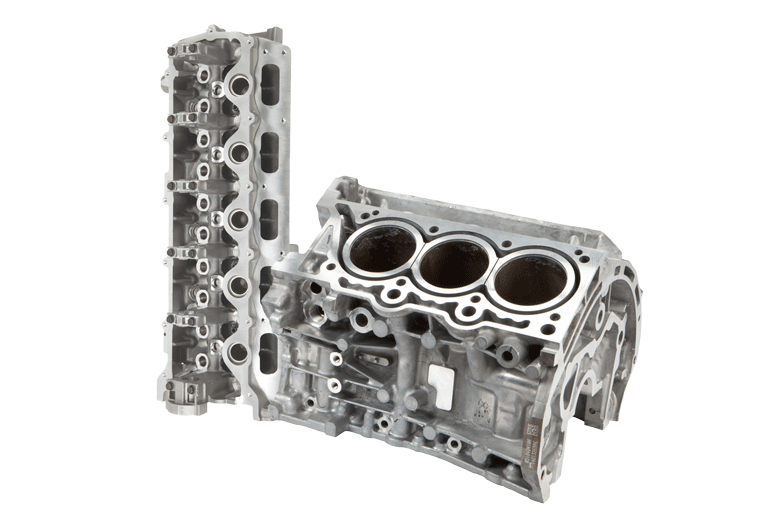

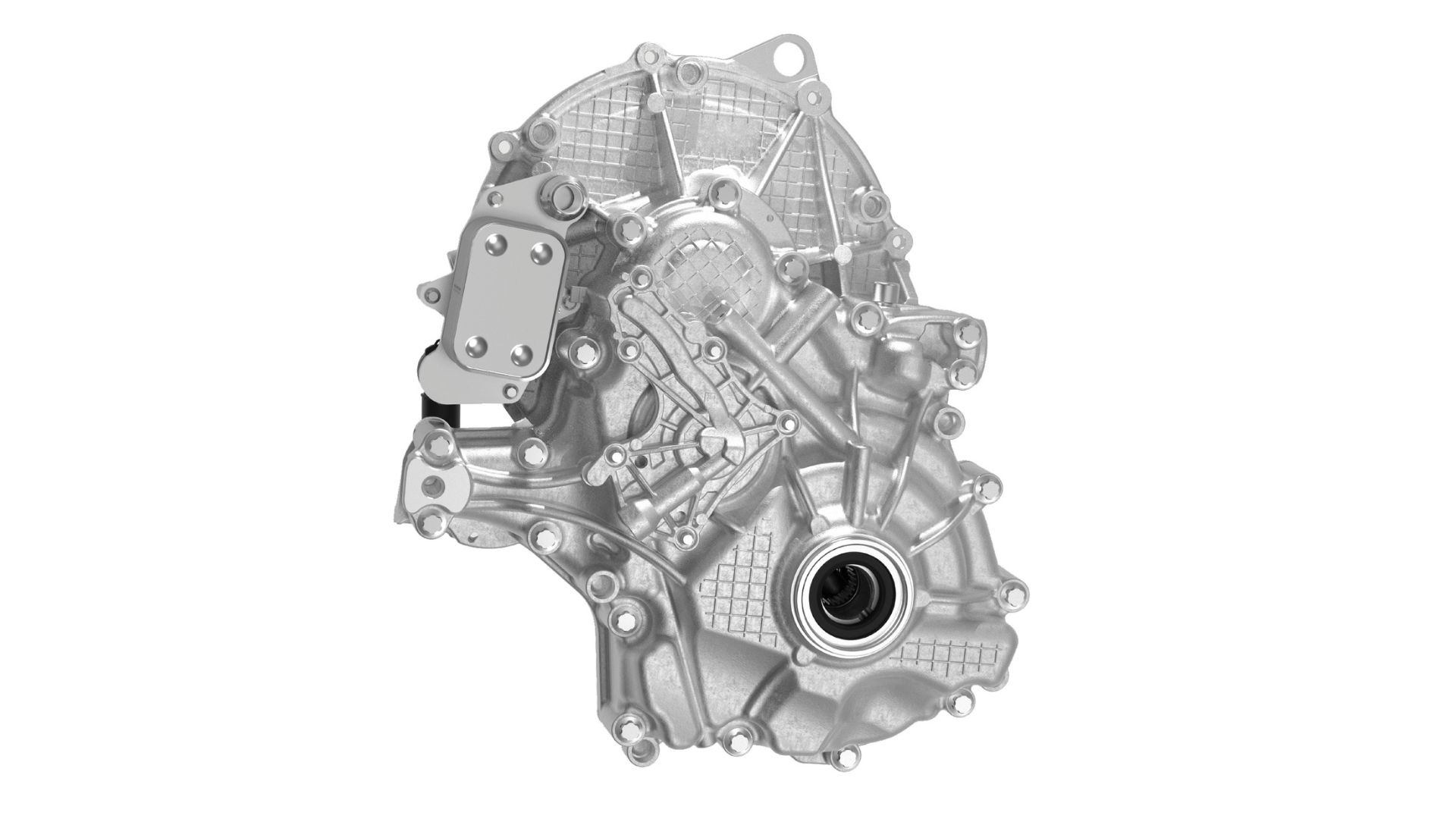

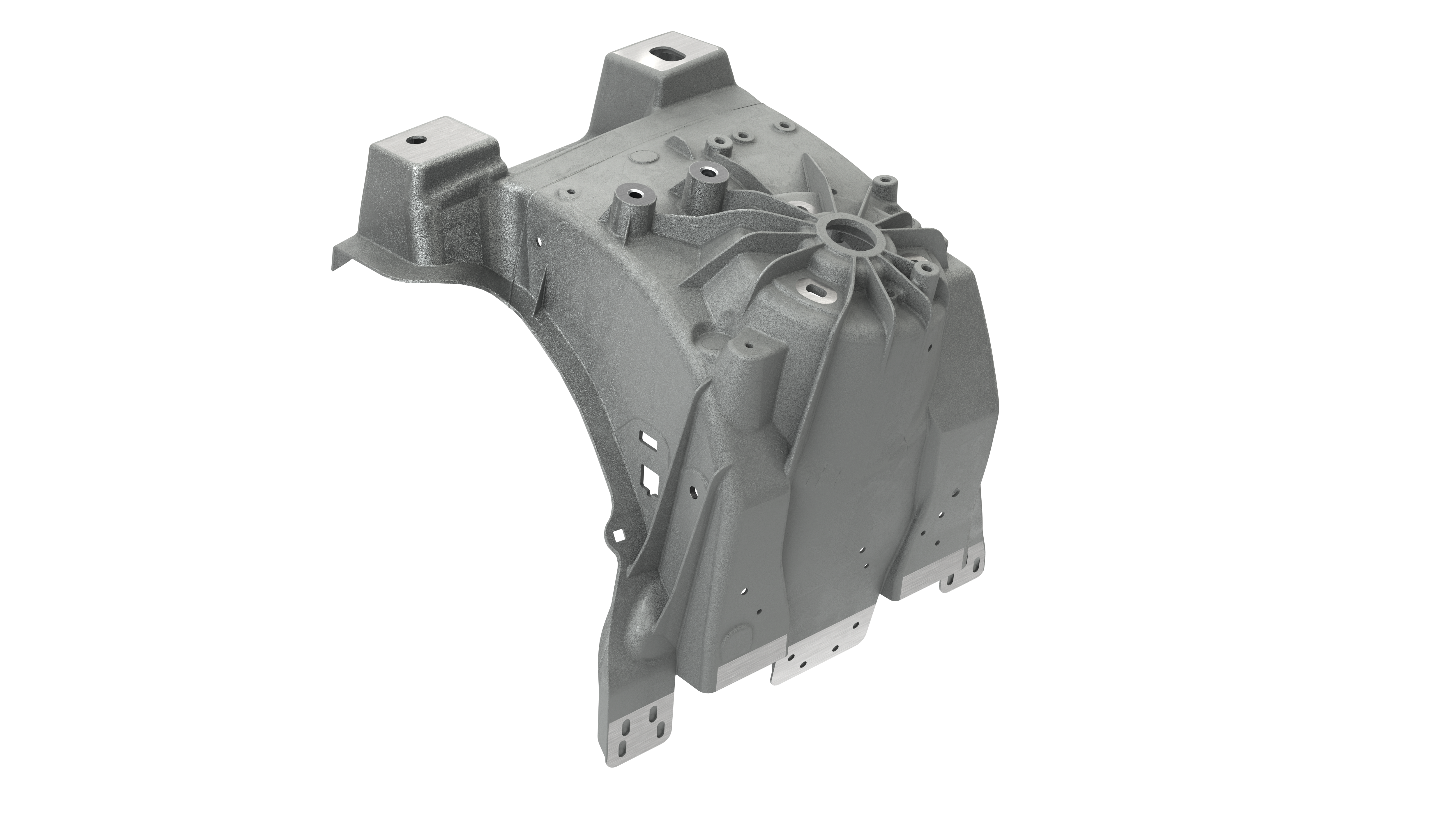

Light Metal Casting

- Gravity & Low Pressure Aluminum Die Casting

- High Pressure Aluminum & Magnesium Die Casting

Mobility

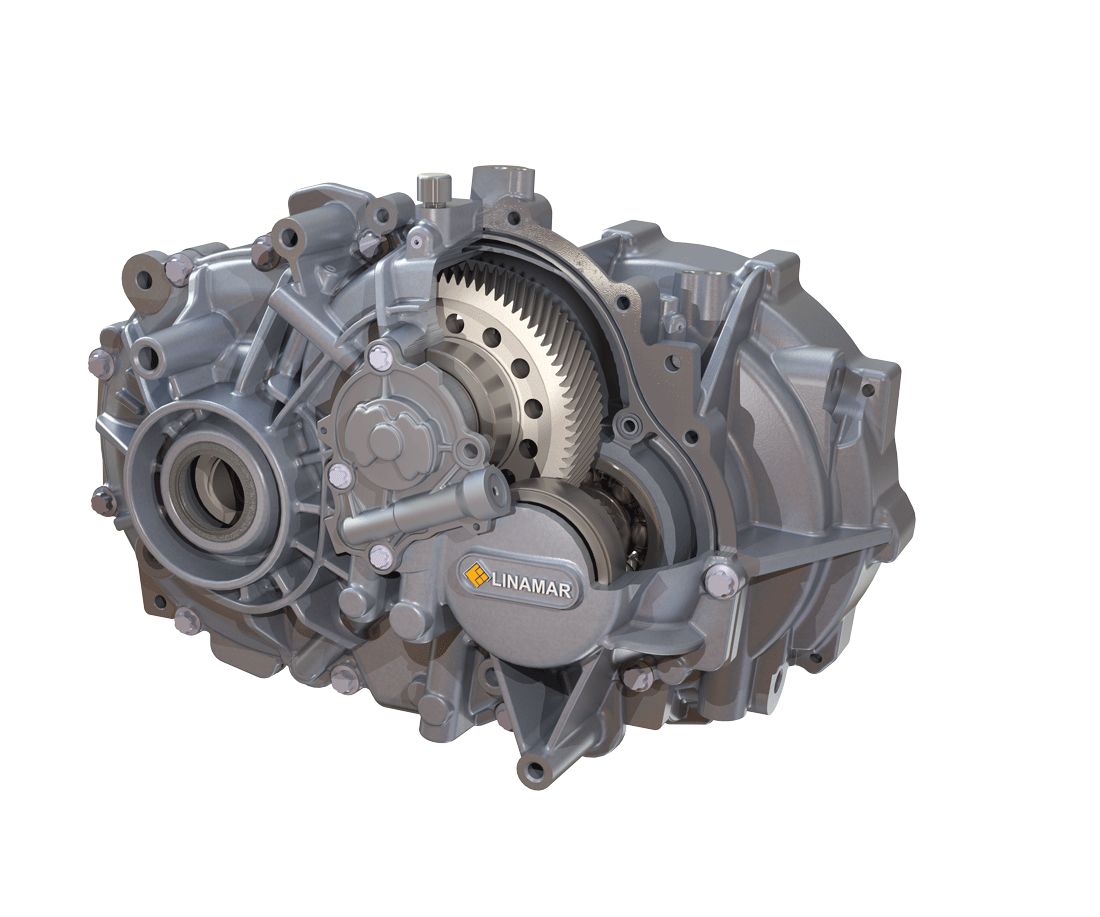

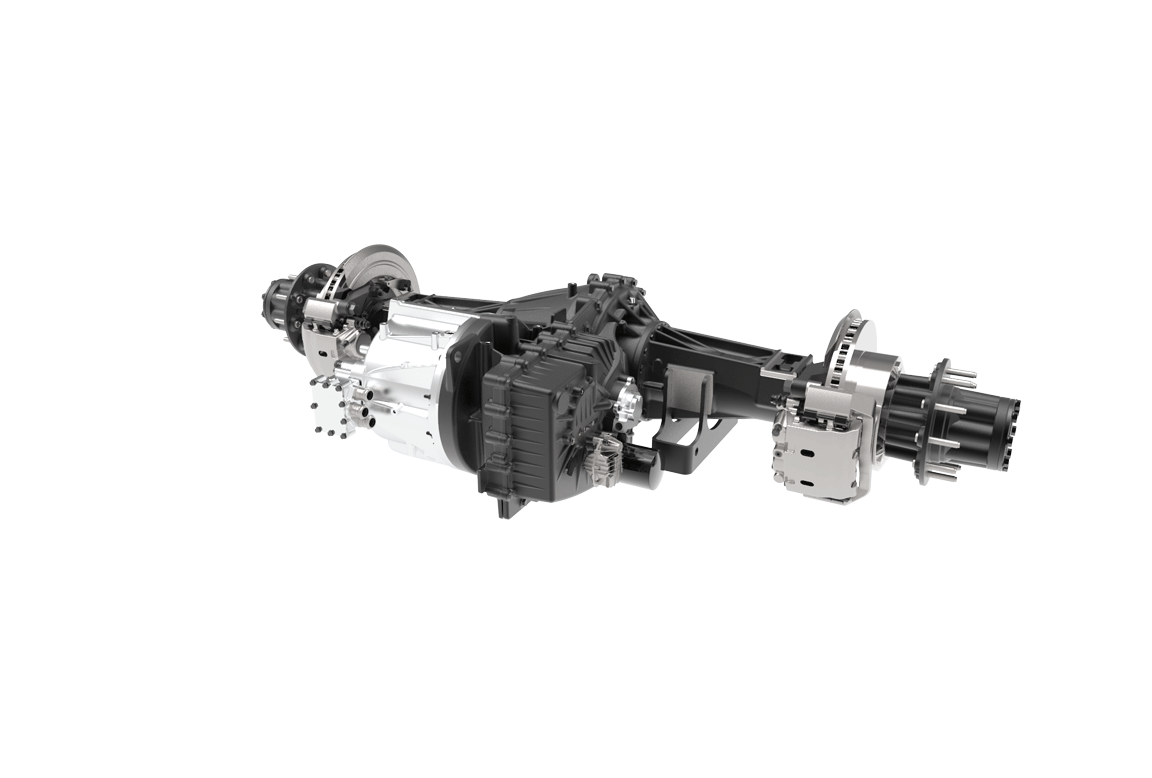

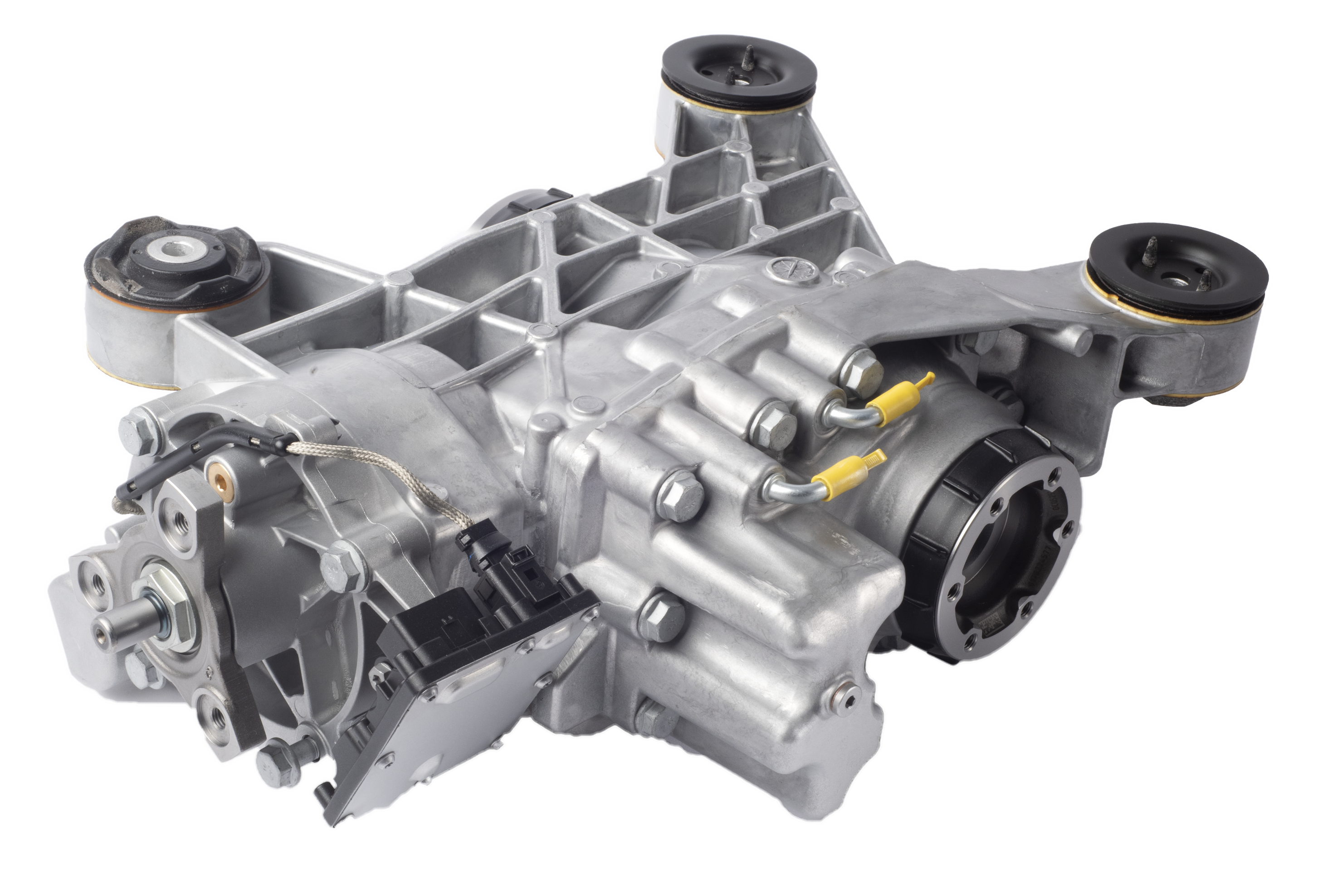

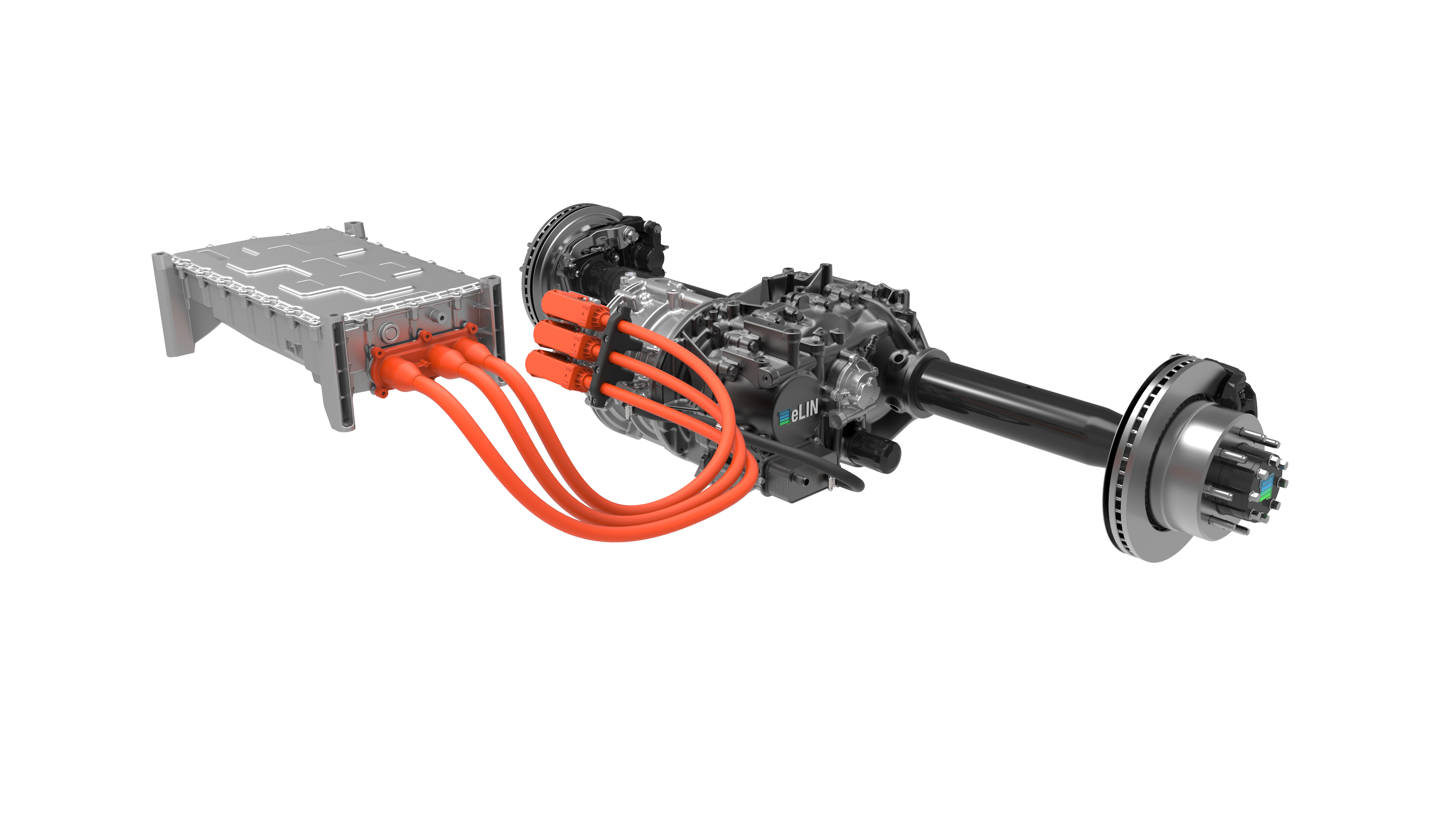

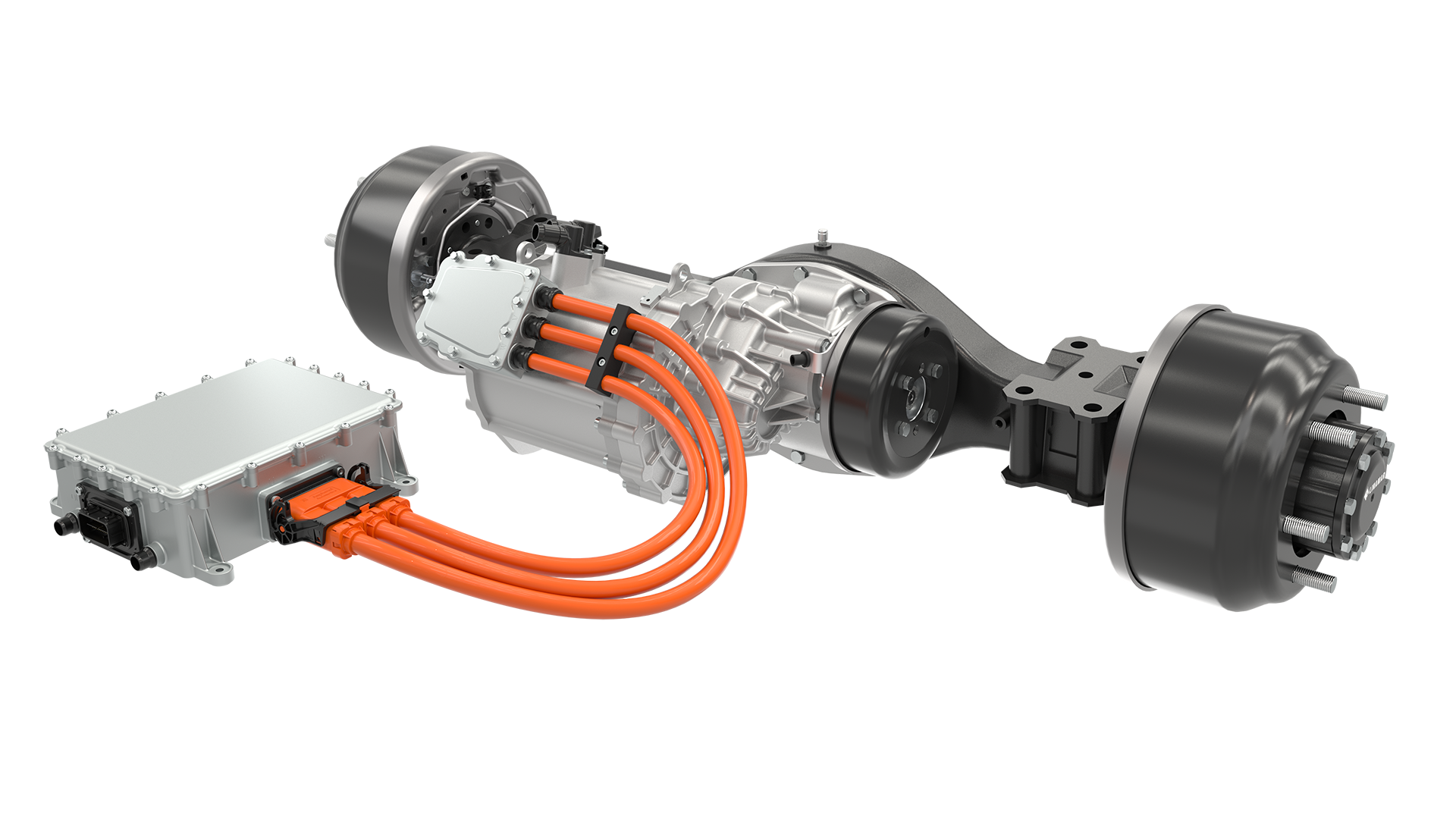

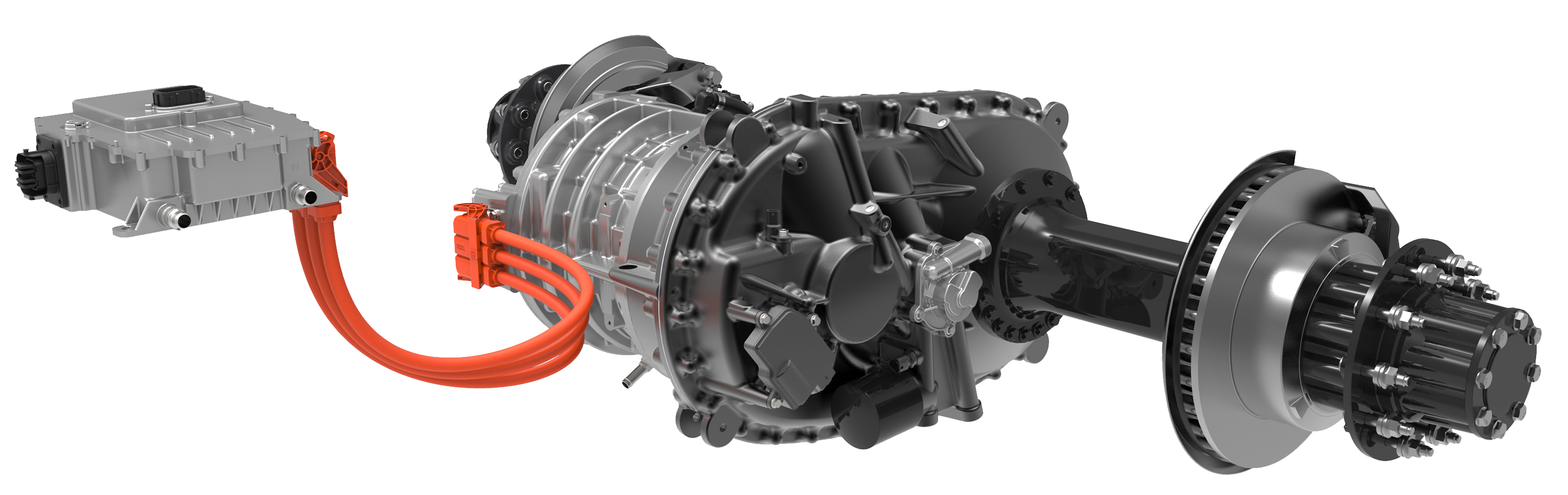

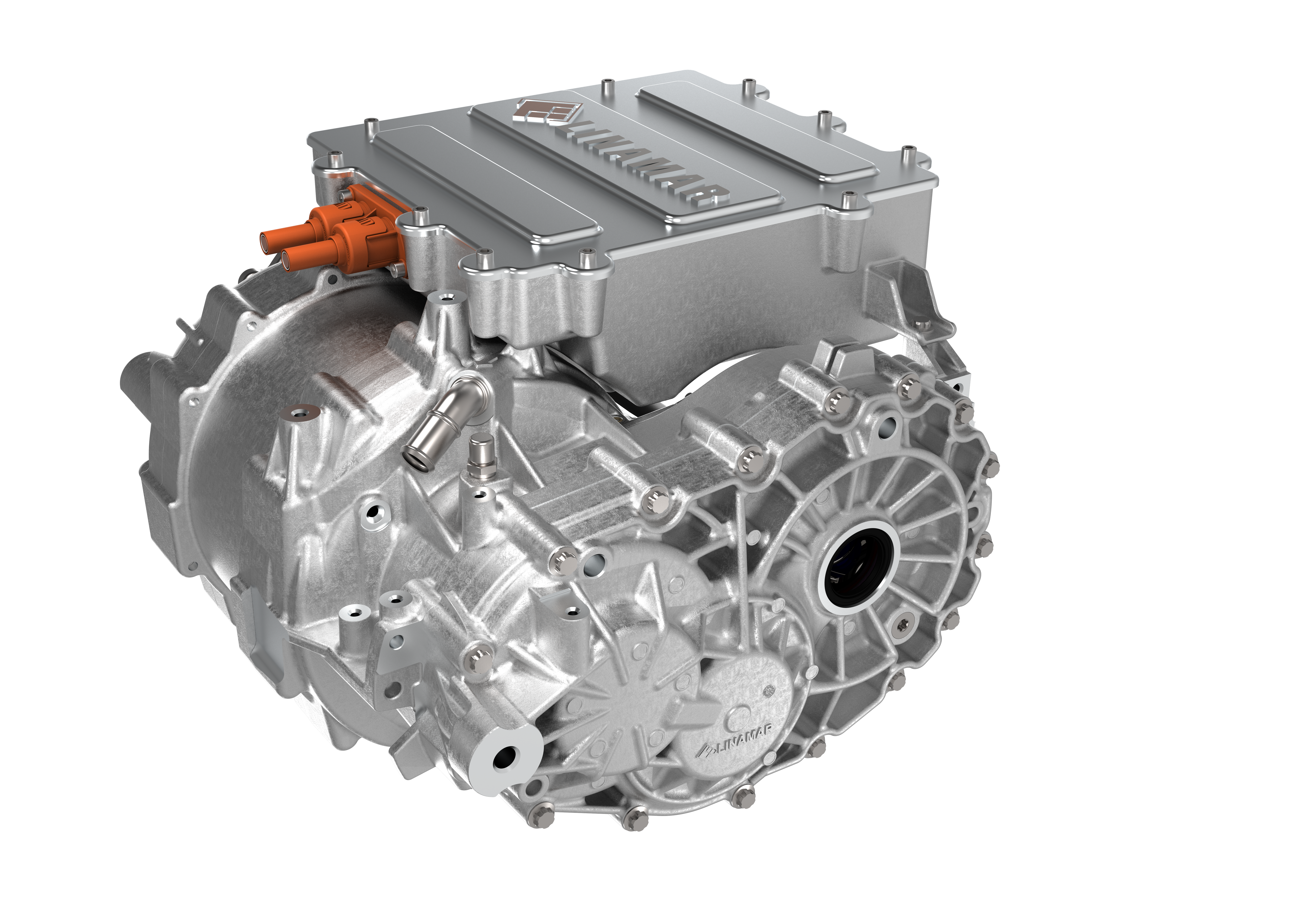

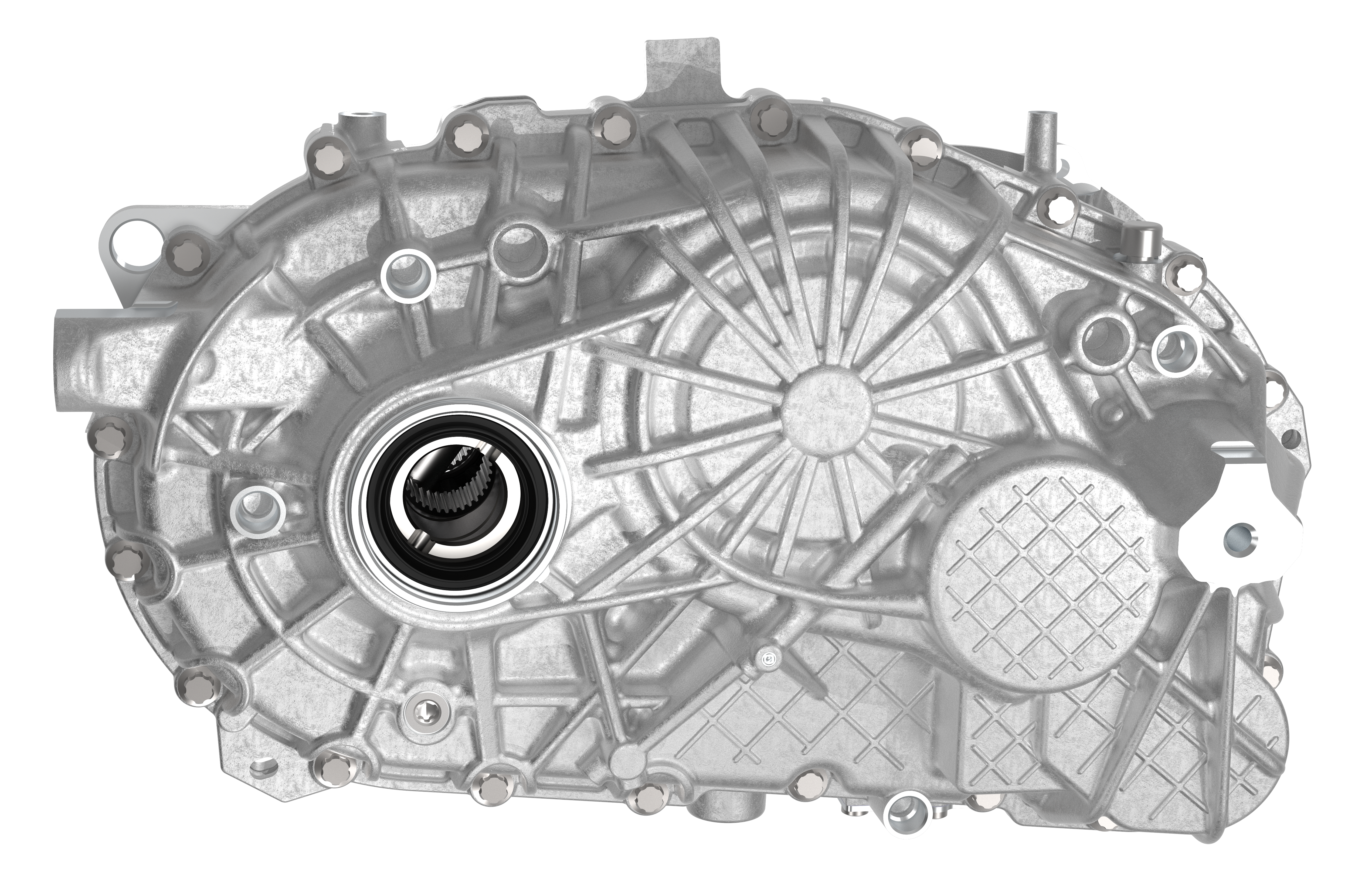

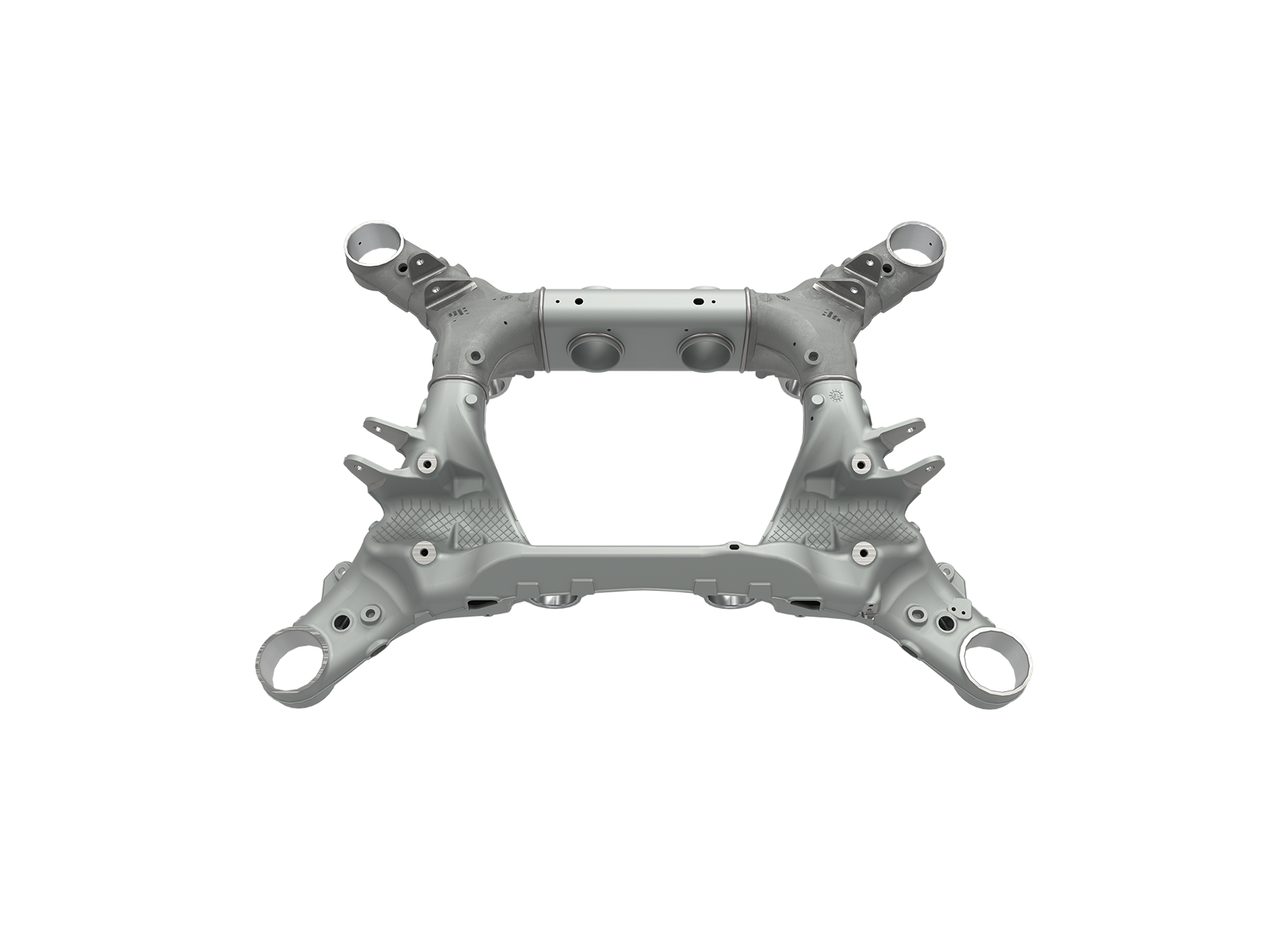

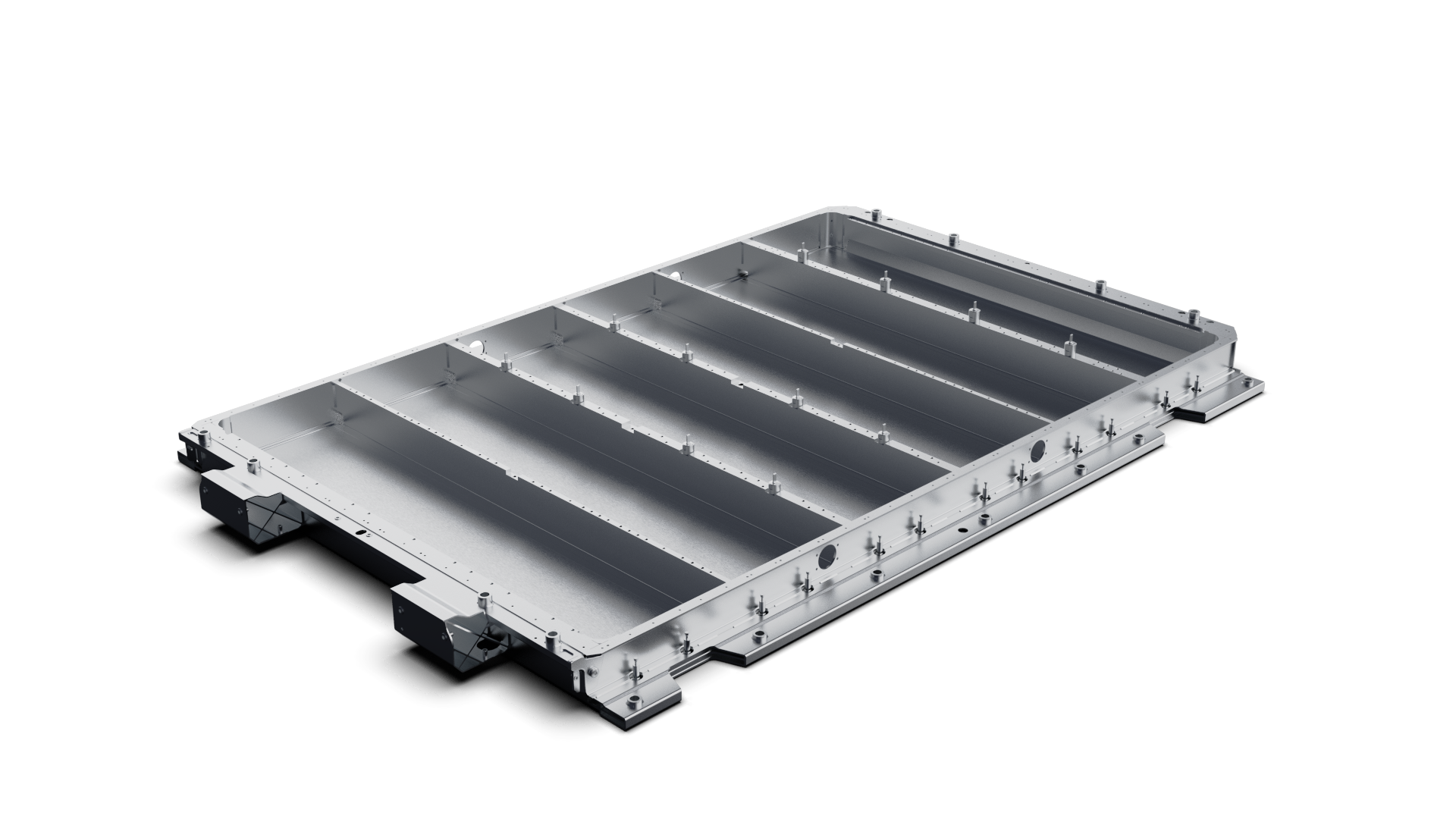

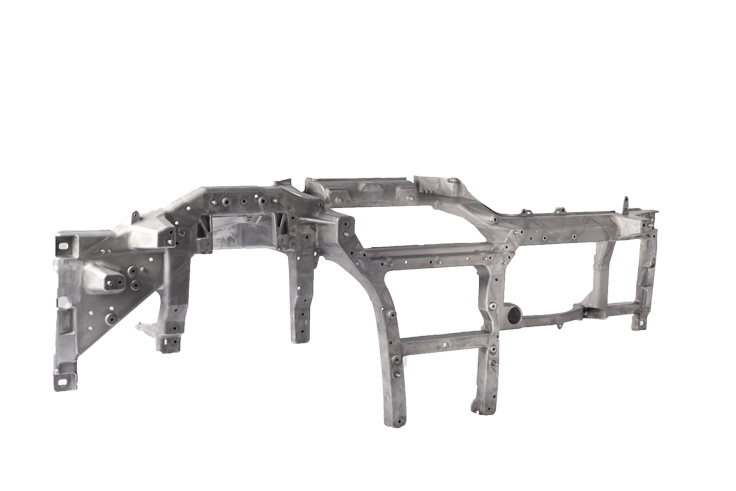

Linamar’s Mobility segment is at the forefront of engineering and product development innovations, specializing in cutting-edge solutions for both electrified and traditional vehicle markets worldwide. Our expertise encompasses propulsion systems, structural and chassis components, energy storage, and power generation.

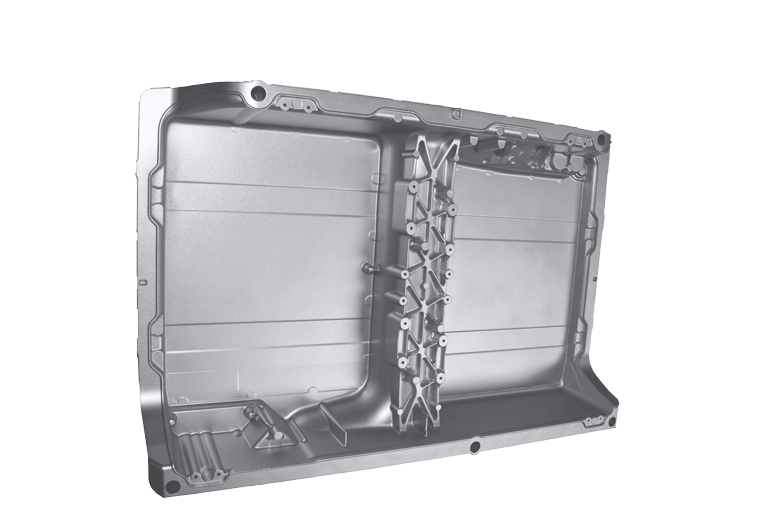

With a focus on advanced manufacturing techniques such as Giga Casting, Die Casting, and Radial Forging, we demonstrate our commitment to engineering excellence. The Mobility segment is organized into three regional groups—North America, Europe, and Asia Pacific—alongside our newly established Structures Group. These vertically integrated operations combine expertise in light metal casting, forging, machining, and assembly to deliver exceptional products.

Our Structures Group is dedicated to providing competitive lightweight innovations for safety-critical components and systems, while the eLIN Product Solutions Group specializes in electrification. Additionally, McLaren Engineering offers design, development, and testing services, ensuring that we remain leaders in the global mobility market. Together, we are shaping the future of mobility with unparalleled expertise and innovative solutions.

Industrial

The Industrial segment is comprised of Skyjack, MacDon, Salford, and Bourgault.

Skyjack manufactures scissor, boom and telehandler lifts for the aerial work platform industry.

MacDon manufactures combine draper headers and self-propelled windrowers for the agricultural harvesting industry.

Salford also supplies the agriculture market with farm tillage and crop fertilizer applicator equipment.

Bourgault specializes in manufacturing advanced agricultural equipment, including air seeders, cultivators, and planters for the seeding and farming industry.

Medical

Linamar MedTech leverages Linamar’s manufacturing expertise and capabilities in precision manufacturing to provide high-quality, cost-effective solutions for Medical Devices and Precision Medical Components.

Our leading-edge technology and deep manufacturing expertise make Linamar MedTech the ideal partner to manufacture and assemble your complex medical devices and components.

To learn more, please contact our team.